TUESDAY

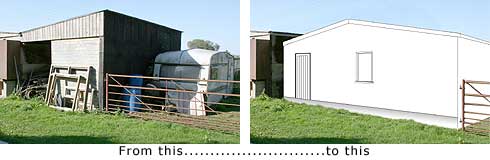

George arrived, as promised, with his helper Roger, to begin erecting the studio…and within minutes the first section was upright.

A quick cup of super-fuel (coffee!) and there was no stopping them.

I couldn’t believe how fast my studio was growing!

And before lunch it was looking like a studio!

WEDNESDAY

The previous Wednesday, as I was in the lane walking the dogs, I was accosted by a driver (no vehicle in sight) who was delivering the roof trusses. The suppliers had sent him to us with an artic (semi-trailer) which couldn’t negotiate the final bend in the lane. With promises to return the next day with a rigid truck… we never saw them again! Fortunately, this is a common problem for George, our builder, and he soon had them racing out to us again and the job could proceed.

George worked hard for the rest of the day and by the time he left the empty shell was beginning to look like a building. I’m glad I chose to have an eight feet high ceiling – standing in the shell it didn’t feel at all oppressive.

THURSDAY

George offered me a deal. He couldn’t find anyone to hire to help him install the plywood ceiling, so if I’d help, he’d return the favour by helping me with the floor and its insulation. That’s a job I knew would take me far longer without George’s knowledge, so I readily agreed. And, as a bonus, I’m now totally sold on compressed air nail guns! What a machine!

By four o’clock we had half the ceiling completed. The sky looked heavy with rain so, rather than risk a downpour overnight, George worked on into the evening installing the roof insulation and the metal box-profile panels over the completed half.

We have 6″ of Rockwool insulation over the ceiling, 4″ in the walls and, as you will see, 4″ of polystyrene insulation beneath the floor. As wood is itself an excellent insulator, and all potential draughty gaps will be filled with foam, this should be a warm and economical space to heat.

That morning George had the windows and doors delivered and he found time to fit the first two.

FRIDAY

Work on the floor began. I had visions of 4″x2″ bearers, packed between with rockwool, and then having to nail down tongue and grooved chipboard. But the expert came up with a far better and faster solution… T&G Chipboard but glued together and laid directly over 4″ of polystyrene insulation. We had the studio area covered in no time at all, and then half of the office and storeroom end, leaving a gap where we could build the dividing wall.

SATURDAY

George began work on the partitioning wall and installed it.

This wall divides the studio from the office and storage/shipping rooms. George was going to build the partition between those two rooms and complete the flooring today… but he was urgently called away to another job and promised to return later this afternoon…

…but he’s not back here yet and that’s as far as we’ve got right up to date. It’s been an eventful but very rewarding week!